Postautomation

Sonderlösungen in den Bereichen: Sortieren, Frankieren und Entwerten von Postsendungen und Paketen.

Technische Details

- Durchsatz: max. 7.200 Briefe / Stunde (Format C4 C4)

- Max. Briefformat: B4, Dicke bis zu 50 mm

- Max. Sendungsgewicht: 5 kg

- Druckhöhe: bis zu 50 mm, Druckposition ist einstellbar Austausch der Druckfarbe durch wechseln der

Kartuschen - Maschinenabmessungen: 3000 mm x 700 mm x 1700 mm (L x B x H)

- Elektrischer Anschluss: 400 V / 50Hz

PRODUKTE / OPTIONEN

- Mail Sorting and Cancelling Machine MSCM

- Modular Mail Sorter MMS

- Cancelling & franking machine FCFM

- Facer Canceller FC

- Letter Facer LF

- Sondermaschinen im Bereich der Postautomatisierung

- Fördertechnik

Cancelling & Franking Machine CMP

Die Entwerte- und Frankiermaschine der CMP series wurde entwickelt um Briefe, welche bisher nur von Hand bearbeitet wurden, zu bedrucken.

Es ist möglich verschiedene Aufdrucke zum Entwerten bzw. Frankieren auf den Umschlag zu drucken. Das Layout kann individuell angepasst und jederzeit über die integrierte Software geändert werden. Es können z.B. Freimachungen, Kundenlogos, Entwertesymbole, Werbetexte und Werbebilder, 2D Codes, Barcodes, usw. gedruckt werden.

Eine integrierte Netzwerkverbindung zum Anschluss an das Hausnetzwerk hilft beim Übertragen von kundenspezifischen Daten für Abrechnungszwecke sowie Statistiken. Die Software kann an individuelle Anforderungen der Kunden angepasst werden.

Die Maschine kann je nach Ausführung Briefsendungen bis zu dem Format B4 und einer maximalen Dicke von 50 mm bearbeiten.

Hierzu werden die Briefe manuell in die Maschine eingegeben. Der Druck erfolgt an der zuvor eingestellt Position durch unser Drucksystem EASY advanced. Anschließend werden die Briefsendungen in Postbehältern gesammelt. Eine Anbindung an Ihre hausinterne Fördertechnik ist ebenfalls möglich.

Flat Cancelling & Franking Machine FCFM

Die Entwerte- und Frankiermaschine FCFM besteht aus mehreren speziellen MMS Modulen. Die Maschine kann Briefsendungen bis zu einer Dicke von 50 mm bearbeiten.

Der Durchsatz mit einem einzigen Bediener kann leicht bis zu 8.000 Sendungen pro Stunde betragen, der maximale Durchsatz liegt bei 12.000 Sendungen pro Stunde.

Es ist möglich zwischen verschiedenen Druckmustern zu wählen um z.B. Briefmarken zu entwerten, Briefe zu frankieren, Kundenlogos und auch Werbung zu drucken. Die Möglichkeiten hierbei sind beinahe unbegrenzt.

Die Bedruckung erfolgt durch das mit millionenfach bewährter Technik ausgestattetem Tintenstrahl Drucksystem EASY advanced. Das Drucksystem druckt das Bild, welches über eine integrierte, einfach zu bedienende Software ausgewählt wird. Dynamische Layouts und Bitmaps ermöglichen ein einfaches und effizientes entwerten, frankieren und bedrucken der Postsendungen.

Die Position des Druckes ist jederzeit einstellbar um speziellen Anforderungen an das Sendungsgut gerecht zu werden.

Die Briefe werden wahlweise in Postbehältern oder einem automatischen Stacker gesammelt. Auch können beide Endstellen kombiniert werden um ein Höchstmaß an Möglichkeiten zu gewährleisten und auf die jeweiligen Bedürfnisse anzupassen.

Hohe Verfügbarkeit, kurze Einarbeitung und Schulung, geringe Wartung, mit einem Wort: Effizient! Viele Möglichkeiten aber einfache Bedienbarkeit war das Ziel beim entwickeln dieser Maschine.

OPTIONEN

- automatische Postbehältermagazine und Fördertechnik

- Kamerasystem POSTMARK CHECKER

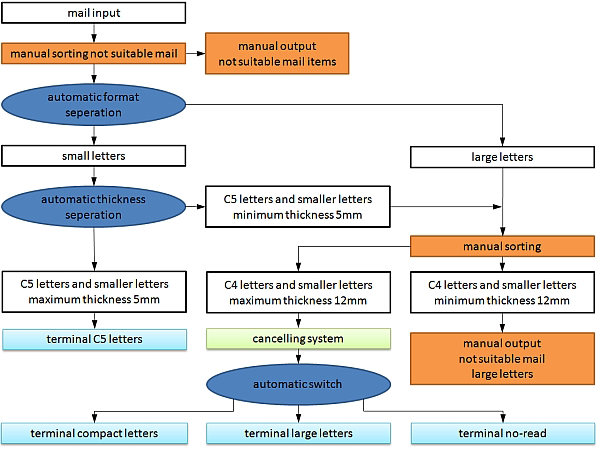

Funktionsweise

TECHNISCHE DATEN

Die Standardversion enthält einen manuellen Vorsortierbereich, die automatische Formatsortierung, eine Dickentrennung für kleinformatige Sendungen, sowie den LLC um Briefmarken auf großformatigen Sendungen zu entwerten.

| Durchsatz |

|

| Endstellen |

|

| Personalbedarf |

|

Um die Maschine mit voller Kapazität zu betreiben, muss der Personalaufwand entsprechend angepasst werden.

- Als Optionen können weitere Module in die MSCM integriert werden. So wird mit der Extended Format Separation EFS die Sortierung um ein weiteres Format ermöglicht oder mit der Thickness Separation Large Letters werden die großformatigen, maschinenfähigen Sendungen automatisch von Maxibriefen mit einer Dicke über 12 mm getrennt.

OPTIONEN

- Standard Letters Channel SLC

- Extended Format Separation EFS

- Thickness Separation Large Letters TSLL

- Facer Canceller FC

- Cancelling Machine Permanent CMP

- Transportsysteme für Behälter

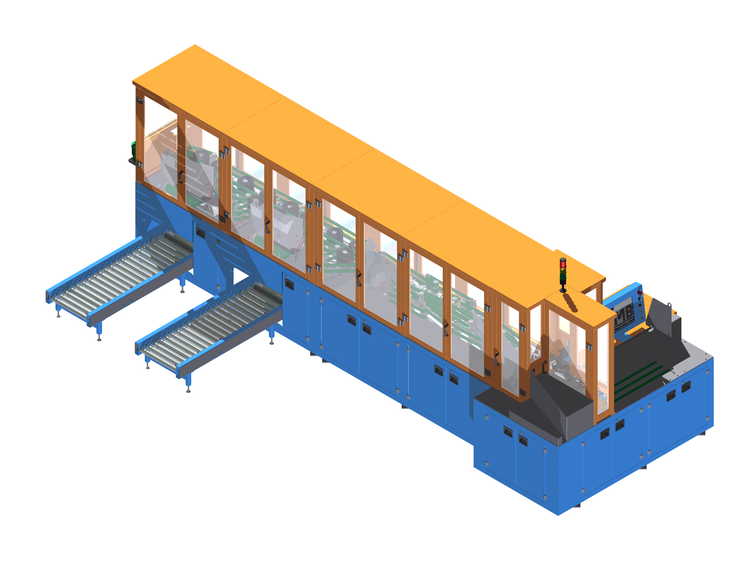

Mail Sorting & Cancelling Machine MSCM

Der neue High Speed Sorter MSCM sortiert automatisch Briefsendungen nach dem Format (Größe & Dicke). Außerdem können Briefmarken durch ein integriertes Entwertesystem abgestempelt werden.

Durch die Modulbauweise kann die Maschine individuell an kundenspezifische Anforderungen angepasst werden.

Der hohe Grad an automatisierten Sortierprozessen und dem dadurch geringem Personaleinsatz, geschieht die Sortierung mit bisher unerreichter Effizienz.

MSCM STANDARD

Die Briefsortiermaschine MSCM Standard sortiert automatisch Briefsendungen nach ihrem Format (Größe & Dicke) und entwertet Briefmarken auf großformatigen Sendungen.

Hierzu werden angelieferte Briefsendungen auf einem Gurtförderer manuell vorsortiert. Es müssen die nichtmaschinenfähigen von den maschinenfähigen Sendungen getrennt werden. Zu den nichtmaschinenfähigen zählen z.B. beschädigte Briefe, offene Zeitungen und Zeitschriften sowie Sendungen, welche einen reibungslosen Sortierprozess stören könnten. Die maschinenfähigen Sendungen gelangen anschließend zur Formattrennung. Standardmäßig geschieht hier die Trennung von Briefsendungen mit dem Format kleiner – gleich C5 (standard size) von den größeren Sendungen (large size). Es sind jedoch, je nach Anforderung, auch andere Sortierungen der Formate möglich.

Kleinformatige Sendungen gelangen daraufhin zur Dickentrennung. Die Dickentrennung ist eine sich um die Längsachse rotierende Sortiertrommel, welche die Trennung der Standardbriefe von den Kompaktbriefen (über 5 mm Dicke) durchführt. Die Standardbriefe werden nach der Dickentrennung über Förderbänder zur Standardbriefendstelle gefördert. Die Endstelle kann in verschiedenen Ausführungen realisiert werden. Bei der MSCM Standard erfolgt die Übergabe an nachfolgende Sortierprozesse über ein Förderband.

Alternativ kann hier unser Standard Letters Channel SLC oder unser Facer Canceller FC angebunden werden. Im SLC erfolgt nochmals eine Formatkontrolle, bevor die Briefsendungen an der Endstelle von dem Bedienpersonal in Behältern gesammelt wird. Der FC entwertet zusätzlich zum SLC die Briefmarken auf den Sendungen. Die Briefe werden dabei entsprechend ausgerichtet, entwertet und anschließend an den Endstellen gesammelt.

Großformatige Sendungen gelangen von der Formattrennung zusammen mit den Kompaktbriefen aus der Dickentrennung zur manuellen Vorsortierung des Large Letter Channels LLC. Hier werden die Sendungen nochmals von dem Bedienpersonal kontrolliert und ein letztes Mal werden nichtmaschinenfähige Groß- und Kompaktbriefe aussortiert. Im LLC werden Briefe bis zu dem Format B4 (250 mm x 353 mm) und einer Dicke bis 12 mm bearbeitet.

Die manuell in den LLC eingegebenen Sendungen werden hochkant zu einer mechanischen Vereinzelung transportiert, anschließend gelangen diese zum Entwertemodul. Dieses besteht aus einem High-Tech Kamerasystem, welches über 100 verschiedene, zuvor eingelernte, Briefmarken erkennen kann. Diese werden dann von einem Tintenstrahl-Drucksystem entwertet. Nach der Entwertung werden die Sendungen entsprechend des Formates den jeweiligen Endstellen zugeführt.

Großbriefe werden in Behältern gesammelt. Bei gefüllten Behältern erfolgt ein automatischer Behälterwechsel und die Übergabe des vollen Behälters an nachfolgende Fördertechnik.

Modular Mail Sorter MMS

Die MMS Maschine besteht aus verschiedenen Modulen, welche miteinander kombiniert, die jeweiligen Bedürfnisse und Anforderungen lösen.

Es gibt verschiedene Module, die jeweils spezielle Funktionen übernehmen. Durch das kombinieren der einzelnen Module ist es möglich, Briefe zu sortieren, Adressen zu lesen, Briefmarken zu entwerten, Briefe zu frankieren. Leicht zu bedienende Software steuert die Maschinen mit ihren vielfältigen Möglichkeiten.

- Einfache Bedienbarkeit

- Geringer Wartungsaufwand

- Effizientes Tintenstrahldrucksystem mit millionenfach bewährter Technik, geringen Betriebskosten. Die Wartung des Systems kann von den Bedienern erfolgen

- Hocheffiziente Kamerasysteme z.B “Postmark Checker”. Postmark Checker kann die Position von bis zu 500 verschiedenen, vorher eingelernten Freimachungen auf C4 Briefen ei einem Durchsatz von 12.000 Briefen / Stunde erkennen

- Durch den modularen Aufbau können auf den Kunden zugeschnittene Maschinen hergestellt werden. Es werden keine unnötigen teuren Features mit gekauft. Sonderwünsche und Neuentwicklungen können ebenso erfüllt werden.

MMS MODULÜBERSICHT

- Automatische Zuführungsmodule

– Verschiedene Feeder für verschiedene Formate und Durchsätze bis zu 50 mm Sendungsdicke - Manuele Zuführungen für unsortierte Briefe, direkt aus dem Briefkasten

- Kamerasysteme und Module

Module für:

– Freimachungen (Briefmarken, Freistempler, …)

– Barcodes

– Adressen

– Postleitzahlen

– 2D – Codes

– Sonderwünsche sind nach Absprache erfüllbar - Druckmodule für verschiedene Druckgrößen um Briefmarken zu entwerten, Briefe zu frankieren, Werbung zu drucken, …

- Weichenmodule

- Wendemodule horizontal und vertical

- Automatische Stacker

- Postbehälterendstellen um Briefe automatisch in Postbehältern zu sammeln

- Sortiermodule für:

– Formatsortierung

– Dickentrennung

– Metalldetektoren